News

Posted: December 6, 2018

Chart: T*SOL

As use of solar heat in manufacturing is still at an early stage, planners and engineers require tools to model and compare differently sized systems and ideas for process integration. In August 2015, researchers working on SHC Task 49, Solar Heat Integration in Industrial Processes, published a list of suitable simulation software. Since then, the developers of these programs have added new features to facilitate the modelling of systems which provide solar heat for industrial processes (SHIP).

The Task 49 researchers evaluated four commercially available tools – TRNSYS, T*SOL, POLYSUN and SOLTERM (see the table below) – as part of a project supported by the IEA Solar Heating and Cooling Programme.

|

Name

|

Type of software

|

Developer

|

Type of collector

|

Type of simulation (time increment)

|

SHIP integration

|

|

TRNSYS

|

Research

|

University of Wisconsin-Madison, USA

|

Stationary and tracking

|

Quasi-dynamic (1 hour)

|

Preset load profiles

|

|

T*SOL

|

Simplified design

|

Valentin Software, Germany

|

Stationary

|

Quasi-dynamic

(6 minutes monthly; 1 hour for a year)

|

Preset load profiles

|

|

POLYSUN

|

Professional design

|

Vela Solaris, Switzerland

|

Stationary and tracking

|

Automated (1 second to 12 minutes); cannot be changed

|

Preset and adjustable load profiles

|

|

SOLTERM

|

Simplified design

|

LNEG, Portugal

|

Stationary and tracking

|

500 seconds

|

Preset load profiles / hourly profiles / weekdays and weekends

|

Some of the features incorporated into four commercially available simulation tools, as listed in the Task 49 report. The document does not contain a detailed description of Solterm, because it was not used by the researchers.

Source: Task 49

Several tools were used in Task 49 (February 2012 to December 2015) to perform calculations based on case studies. Feedback was summarised as follows:

TRNSYS is flexible as it allows users to choose from a variety of models for collectors, storage tanks, controllers etc. Therefore, selecting another model for the same case study might lead to different results, so that TRNSYS is less practical for rather general studies. The program should be chosen whenever the description of the system is very detailed and components seem well-specified.

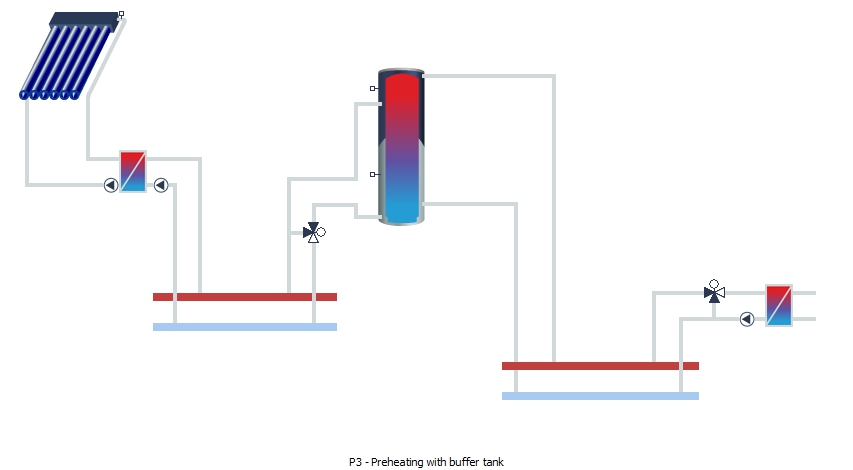

T*SOL is highly intuitive and takes little time to use. To model systems supplying industrial solar heat, it provides a number of standard configurations to allow for a quick start to calculating energy yields and system economics for a wide variety of industrial applications, such as preheating make-up water and heating closed process loops. Due to the preconfigured systems the modelling of complex hydraulic set-ups and corresponding control strategies (especially on the process side) is limited.

Polysun is, because of its graphical interface and component-based structure, intuitive and fast. The program offers some preconfigured models suited for basic solar process heat applications, such as preheating make-up water, heating closed process loops and integrating solar thermal devices into a system of steam pipelines. The process side includes a simplified heat sink design and may be extended and more detailed specified by the user. Additionally, the temperature of the process cannot exceed 250 °C.

The researchers found several limitations across the different tools:

- Time increments are too large for rapid changes (e.g. in operation).

- Limited number of hydraulic schemes for SHIP applications.

- Limited options to model process heat applications (preset load profiles and low number of heat sinks).

The program developers have released updates to remove relevant limitations and expand the scope of SHIP plant models. “T*SOL 2018 now has two more hydraulic SHIP models with up to six solar circuits and up to six heat sinks, including one for process heat,” said Denise Dawes, International Marketing Manager at Valentin. Polysun programme administrator Andreas Wolf said a recent update of Polysun added a function to specify inlet and return temperatures for process heat applications via CSV files.

Software tools and organisations mentioned in this article: