21.06.2016

All deliverables of the IEA SHC Task 49 now available online!!!

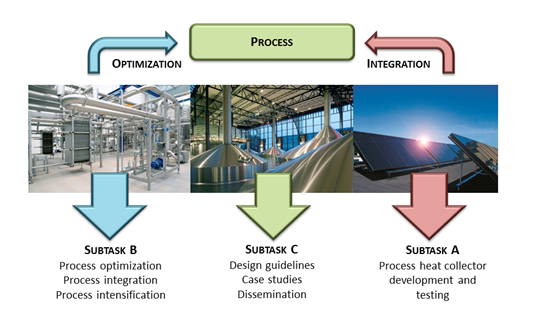

Subtask A: Process heat collector development and process heat collector testing

Lead Country: Germany (Dr. Pedro Horta - Fraunhofer ISE)

Initially: Switzerland (Dr. Elimar Frank - SPF)

Subtask B: Process integration and Process Intensification combined with solar process heat

Lead country: Austria (DI Bettina Muster – AEE INTEC)

Subtask C: Design Guidelines, Case Studies and Dissemination

Lead country: Germany (Dr. Werner Platzer - Fraunhofer ISE)

08.01.2016

Operating agent Christoph Brunner @ SHC in Istanbul:

How can solar heat be used for industrial processes? Find out in this video interview with Christoph Brunner, Head of the department Industrial Processes and Energy Systems at the Austrian research facility AEE – Institute for Sustainable Technologies (AEE-INTEC). This video was recorded at the SHC 2015 conference in Istanbul by solarthermalworld.org.

02.11.2015

Industrial Workshop on solar process heat:

The final Industrial Workshop on solar process heat - Results and findings of the EU FP7 Project InSun was held together with a conference on small-scale CSP at the Auditorium Technology Park of Sardena Richerche on September 25th, 2015 in Pula/Sardinia, Italy. Both the conference and the workshop provided open platforms for discussions, proposal and solutions, representing a concrete opportunity to coordinate actions and resources for the diffusion of small-scale CSP technology in Sardinia and in the Mediterranean region and for its integration in several industrial processes.

More infos on: http://www.sardegnaricerche.it/en/

22.05.2015

8th Task Meeting + Industrial Workshop in FRANCE:

Please find all the details on our dedicated webpage for the Industrial Workshop.

02.03.2015

New Task-Deliverables ONLINE! Download reports on solar heat integration and process integration!

Integration Guideline (B2) - Download here

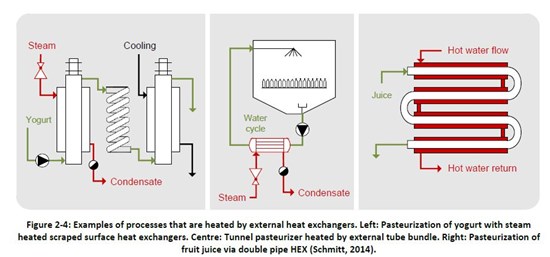

Guideline for solar planners, energy consultants and process engineers giving a general procedure to integrate solar heat into industrial processes by identifying and ranking suitable integration points and solar thermal system concepts.

Exemplary extract from B2: Typical thermal processes where solar heat integration is possible

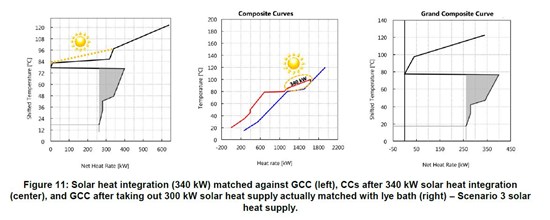

Methodologies and Software Tools for Integrating SHIP (B1) - Download here

This document is primarily intended for the process integration community, and aims to present specific issues of, and solutions/approaches for, the integration of solar heat into industrial processes. It does not describe Process Integration nor present the basics of Pinch Analysis.

Readers not familiar with these topics should refer to the Task 49 report, Integration Guideline, Chapter 4, which is targeted to the community of solar engineers.

Exemplary extract from B1: Solar heat integration via Pinch analysis

29.9.2014

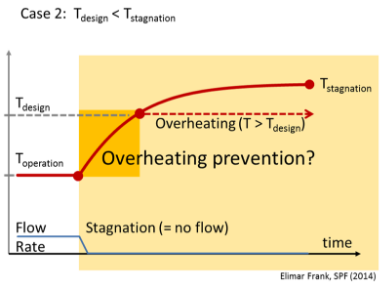

Technical Report A.1.2 - Overheating prevention and stagnation handling in solar process heat applications

Stagnation handling in SHIP applications - Download here

Solar process heat plants have to operate totally reliable in all the operation modes that may occur. Other than for conventional closed hot water or steam supply systems solar thermal applications in general require specific technical solutions to cope with the phenomenon of stagnation.

This report gives an overview about topics related to stagnation and overheating in general and specifically with regard to solar assisted process heat applications.

The technical report will be soon ready for download.

20.3.2014

Official start of the Solar Heat for Industrial Processes - SHIP database

The Solar Heat for Industrial Processes - SHIP database has been created in the framework of the IEA Task 49/IV. This online database contains a worldwide overview on existing solar thermal plants which provide thermal energy for production processes for different industry sectors. Each plant description contains a number of information e.g. about the size of the collector field, collector technology or integration point in the production process. An initial survey has been developed and sent out to different solar companies by AEE INTEC (www.aee-intec.at). The returned data has been collected, structured and integrated into the database by them. All the programming work for the database’s structure and design has been done by PSE (www.pse.de).

Now the user of the database has the possibility to extract detail information from all identified solar thermal plants and create statistics like the share of collector technologies, size of the collector field per country or industry sector and cost per square meter. The SHIP - database is a living platform and will grow continuously.

27.2.2014

Retanning (leather industry) and Leaching (mining industry) in the focus of solar heat

The retanning process is a common process to be targeted by solar process heat. Currently 9 applications are successfully operating with a total gross solar area of 5,317 m². 7 of these

Retanning in Thailand, 1890 m²

Source: Aschoff Solar

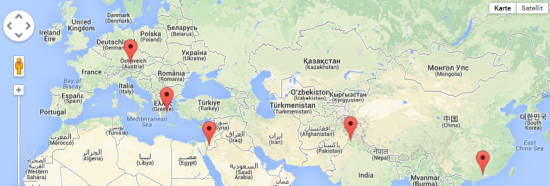

Location of the leather factories with SHIP-applications.

Worldwide SHIP applications in the retanning process of leather industries - Source: AEE INTEC

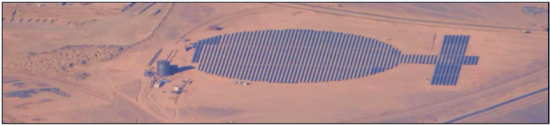

The Codelco copper mine in Chile not only has the world's largest SHIP application, but also the largest solar thermal collector field (39,300 m²). The system keeps water at a constant temperature for the leaching process. A similar, but smaller application (790 m²) exists in Cyprus.

Codelco copper mine in Chile

39,300 m²

Source: Sunmark

24.9.2014

Brewery Göss

A 1,470 m² solar thermal collector field provides hot water for the mashing process in the brewery Göss, Austria. The mashing process has been changed to a low-temperature-process by integrating additional heat exchanger plates. Hot water is now used instead of steam, which allows better renewable energy integration.

Source: AEE INTEC

The project has been realised in the frame of the FP7-project SolarBrew, where Göss has been the first of three HEINEKEN-breweries to be equipped with a large solar thermal collector field. The other two breweries in Vialonga, Portugal and Valencia, Spain are currently in the planning and implementation phase. The total installed capacity of these plants will be 5.08 MWth corresponding to a 7,270 m² collector area.

Follow this link to send us information on your SHIP application:

Survey SHIP applications